processing graphite powder

Graphite

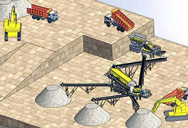

Prominer provides the complete solution of graphite processing plant including crushing, grinding and flotation plant to make natural flake graphite

More

Graphite Powder - an overview ScienceDirect Topics

Lifeng Wang, ... Jun Yang, in New and Future Developments in Catalysis, 2013. 6.2.3 Graphite and Graphite Nanofiber. Bulky graphite powder adsorbed almost negligible amount of hydrogen, i.e., 0.037 wt% at 60 bar and 298 K [14], because of its stable and inaccessible structures for hydrogen.To improve the hydrogen storage in graphite, two common approaches, ball-milling

More

Graphite Powder Grinding Mill for Graphite Processing

1.Graphite ore ball mill investment is small. 2.The continuous operation of a graphite ball mill can achieve long-term operation and create high efficiency in the later period. 3.The graphite stone grinding mill adopts advanced technology, which has obvious energy-saving and environmental protection effects, and low operating cost.

More

Forming process of graphite material

2019-7-23 The forming process was: pressure 100-140 MPa, boost time (> 20 min), holding time 5-30 min, relief time (> 15 min). After calcination, impregnation and graphitization, the density, compressive strength and isotropy of isostatic pressing graphite products are above 1.8g/cm3, above 70MPa and below 1:1:1. Qiu Tingju, Xie Zhiyou and Gao Jiang ...

More

Graphite powder specifications, testing methods and

2022-5-31 Graphite powder is widely used. According to its different uses, graphite powder can be divided into the following specifications: Flake graphite powder; Flake graphite powder is the most widely used, and it is also the raw material for processing other graphite powder. Flake graphite has good toughness, good thermal conductivity, and corrosion resistance.

More

Processing methods of different graphite ore

China has established a graphite refining and fine powder processing production line in Nanxu, Beishu, Liumao, Xinghe and other graphite processing plants. The purification method is mainly chemical purification. Graphite chemical purification of the most mature process is the use of caustic and graphite melting at 700 ℃, after washing to ...

More

Graphite manufacturing process - GAB Neumann

2022-7-1 Impervious graphite for process equipment applications is manufactured in two main steps. First synthetic graphite is manufactured. Then this material is impregnated with phenolic resin to make it impervious and

More

GRAPHITE MANUFACTURING PROCESS

2019-2-4 graphite and secondary graphite scrap are loaded and stored in raw materials silos. At the first step the raw materials are pulverized (ground) in crushers and ball mills. The resulted powder is conditioned according to the particles size distribution (screening). The last step of powder preparation process is blending the powder with a binder ...

More

Understanding the dust collection of graphite powder

2022-6-14 Graphite powder is a kind of mineral powder, mainly composed of carbon, soft, black and gray; It is greasy and can pollute the paper. The hardness is 1 ~ 2, and the hardness can increase to 3 ~ 5 with the increase of impurities in the vertical direction. The specific gravity is 1.9 ~ 2.3. Under the condition of isolating oxygen, its melting ...

More

China Powder Graphite Processing Factory and Suppliers

2021-11-19 Powder Graphite Processing Related Videos From Youtube Christine 2021.04.22 22:56:16 The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

More

Graphite Powder - an overview ScienceDirect Topics

Lifeng Wang, ... Jun Yang, in New and Future Developments in Catalysis, 2013. 6.2.3 Graphite and Graphite Nanofiber. Bulky graphite powder adsorbed almost negligible amount of hydrogen, i.e., 0.037 wt% at 60 bar and 298 K [14], because of its stable and inaccessible structures for hydrogen.To improve the hydrogen storage in graphite, two common approaches, ball-milling

More

Forming process of graphite material

2019-7-23 The forming process was: pressure 100-140 MPa, boost time (> 20 min), holding time 5-30 min, relief time (> 15 min). After calcination, impregnation and graphitization, the density, compressive strength and isotropy of isostatic pressing graphite products are above 1.8g/cm3, above 70MPa and below 1:1:1. Qiu Tingju, Xie Zhiyou and Gao Jiang ...

More

Graphite Powder Grinding Mill for Graphite Processing

1.Graphite ore ball mill investment is small. 2.The continuous operation of a graphite ball mill can achieve long-term operation and create high efficiency in the later period. 3.The graphite stone grinding mill adopts advanced technology, which has obvious energy-saving and environmental protection effects, and low operating cost.

More

Graphite Powder AMERICAN ELEMENTS

Graphite powder is often used as an additive in coatings such as paint and epoxy. Powders are also useful in any application where high surface areas are desired such as water treatment and in fuel cell and solar applications. Nanoparticles also produce very high surface areas. Our standard powder particle sizes average in the range of - 325 ...

More

GRAPHITE MANUFACTURING PROCESS

2019-2-4 graphite and secondary graphite scrap are loaded and stored in raw materials silos. At the first step the raw materials are pulverized (ground) in crushers and ball mills. The resulted powder is conditioned according to the particles size distribution (screening). The last step of powder preparation process is blending the powder with a binder ...

More

Graphite ore flotation processing flow chart

This graphite ore flotation plant including: (1) Preparation processing: first and second crushing, and coarse milling. (2) Flotation processing: rough separating, sweeping separating and fine separating. (3) Concentrates treatment:

More

Highly Conductive Expanded Graphite Powder

SIGRATHERM graphite powder. SGL Carbon's SIGRATHERM GFG is a highly conductive flexible graphite powder. It is used in a wide variety of applications where thermal or electrical conductivity is essential. For instance, it is suitable

More

The processing process of graphite electrode - Iron and

2021-5-7 The process of high temperature (1200-1500°C) heat treatment of carbonaceous raw materials in isolation of air is called calcination. Calcining is the first heat treatment process in carbon production. Calcining causes a series of changes in the structure and physical and chemical properties of various carbon raw materials.

More

Graphite electrode manufacturer ,graphite powder ...

2) Liaoyang Penglong Furnace Burden Processing Factory, mainly engaged in producing and processing graphite electrodes and secondary products of graphite scraps and graphite powder. 3) Liaoning Zhonghe Carbon Material Technology Co., LTD., mainly engaged in the production and processing of all kinds of efficient recarburizers.

More

Graphite Powder Processing Plant Mineral

2019-10-31 The production line of the graphite powder processing line can reduce the ratio of product/raw material to 1:1.7, and the line is equipped with laser precision welding rotor and adjustable speed high speed motor,

More

Graphite Powder - an overview ScienceDirect Topics

Lifeng Wang, ... Jun Yang, in New and Future Developments in Catalysis, 2013. 6.2.3 Graphite and Graphite Nanofiber. Bulky graphite powder adsorbed almost negligible amount of hydrogen, i.e., 0.037 wt% at 60 bar and 298 K [14], because of its stable and inaccessible structures for hydrogen.To improve the hydrogen storage in graphite, two common approaches, ball-milling

More

Graphite Powder AMERICAN ELEMENTS

Graphite powder is often used as an additive in coatings such as paint and epoxy. Powders are also useful in any application where high surface areas are desired such as water treatment and in fuel cell and solar applications. Nanoparticles also produce very high surface areas. Our standard powder particle sizes average in the range of - 325 ...

More

Graphite manufacturing process [SubsTech]

2020-6-13 The scheme of the die molding method is presented in the picture: The die molding process consists of the following stages: Die filling At this stage a controlled amount of the powder is fed into the die cavity. Compaction Upper punch moves down and presses the powder at room or elevated temperature with a predetermined pressure. The pressure ...

More

Application of graphite powder-Company News-News

2020-1-1 Graphite powder has a hardness of 1 to 2, a specific gravity of 1.9 to 2.3, and a boiling point of 4250 ° C. It is one of the minerals resistant to high temperatures, but it is relatively stable at room temperature. ... can be used without processing or a little processing, thus saving a lot of metal. Production of powder metallurgy processes ...

More

Graphite Manufacturing Process – American Carbon

After a 3-4 week heating and cooling process, the carbon rods have been fully converted to a graphite rod. The next step is machining the rods to tolerance, for American Carbon’s graphite anodes these tolerances are +1/4”, -0” on diameter and +1”, -0” on length. Some anodes are also predrilled for center connections.

More

Graphite ore flotation processing flow chart

This graphite ore flotation plant including: (1) Preparation processing: first and second crushing, and coarse milling. (2) Flotation processing: rough separating, sweeping separating and fine separating. (3) Concentrates treatment:

More

Graphite Processing Parts - 六工石墨英文网站

Graphite Powder Graphite Processing Parts Graphite Raw Material Graphite Rod Graphite Rotor 豫ICP备19029825号-1 About Liugong About Liugong Contact Liugong Application Industry Process And Equipment News Product Center Graphite Raw Material ...

More

High Quality Development of Graphite Resource and ...

Furthermore, this paper proposes the following measures: (1) establishing a technology innovation system that focuses on the deep processing of graphite; (2) optimizing the allocation of resources and boosting the development of green graphite plants and mines; (3) strengthening the capacities of platforms to consolidate the technological ...

More

Skaland Graphite Operation - Mineral Commodities Ltd

Processing. Crushed ore from the mine is dumped into a ROM ore bin and conveyed to an autogenous mill followed by a front-end, open-ended milling circuit before processing via a three stage flotation and cleaner circuit with multiple sub-stages in each stage The Skaland Processing Facility treated ∼40ktpa of ore in 2019 and produced a graphite flake concentrate of ∼91%C.

More- << Previous:Concassage Mahine A Vendre

- >> Next:Cylindrical Grinding Iran