belt conveyor head chute

Design Considerations of the Transfer Chute Martin Engineering

网页The volume of the head (discharge) chute around the discharge pulley is usually dictated by the general arrangement of the conveyors, access requirements for service, and the

More

Considerations For An Optimal Conveyor Transfer Chute

网页2020年7月10日 A belt-to-belt transfer chute is fed material from the upper conveyor. Typically, material waterfalls off the belt into the head chute compartment. From here it

More

Components of a Standard Belt Conveyor - Martin Eng

网页A conveyor’s head, or discharge, end will usually consist of the head pulley, a discharge chute along with a belt-cleaning system, a dribble chute, and other equipment to monitor

More

Conveyor Chute Design - BEE - Biomass Engineering Equipment

网页2022年4月12日 When a chute discharges onto a belt conveyor, engineers should consider the relative velocity of the falling material relative to the belt. If the material lacks

More

Conveyor Chute Lining Chute and Skirt Lining - ASGCO

网页Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build,

More

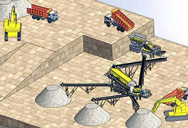

Chute Conveyor System in Material Handling - OpEx

网页2011年3月5日 In general, a chute conveyor is ideal for the following: Unit/Bulk + On-Floor + Accumulate. Inexpensive. Used to link two handling devices. Used to provide accumulation in shipping areas. Used to

More

The Functions and Types of Belt Conveyor Head Hopper

网页2020年3月3日 The head hopper and chute are important devices for connecting belt conveyors, the material will be loaded to link connected conveyor via the conveyor

More

Conveyor Parts and Each of Their Functions - YaleTools

网页5. Discharge Chute. Discharge chute is an outlet for goods that are loaded by the conveyor. 6. Head Pulley. The head pulley is a pulley located at the front end of the belt where the

More

MINIMIZING BELT WEAR AND DAMAGE FROM OPTIMIZED

网页The original chute configuration consisted of a single discharge conveyor, an asymmetrical gate, and two legs, one of which has a rock box at its discharge. The design throughput

More

Components of a Standard Belt Conveyor - Martin Eng

网页A conveyor’s head, or discharge, end will usually consist of the head pulley, a discharge chute along with a belt-cleaning system, a dribble chute, and other equipment to monitor and maintain flow. A transfer point is where the bulk material moves from on piece of equipment to another .

More

Conveyor Chute Lining Chute and Skirt Lining

网页Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build,

More

Transfer Chutes - Jenike Johanson

网页Though the transfer chute itself may appear to be only a small or low-cost part of the equipment train, it can easily become a costly bottleneck and maintenance nightmare due to: Plugging or buildup Abrasive wear of

More

Belt Conveyor Dribble Chutes - Martin Eng

网页Dribble chutes return material to the cargo flow Martin Engineering Belt Conveyor Dribble Chutes On conveyors where the cleaning systems are positioned so the material removed from the belt does not freely return

More

Belt Trippers Belt Plows - FEECO International Inc.

网页As the belt passes over the upper pulley, the material is discharged from the belt into a collection chute. The material is then diverted to one side or both sides of the belt for discharge, or back onto the belt if the desired

More

Chutes - Outotec

网页Chutes are used to transport material from one process step to another. When material is fed into a process or discharged from it, chutes collect, convey and prepare the material flow for the following processing phase. Chutes are used with crushers, feeders, conveyors, stackers, and grinding mills. Contact our sales experts Benefits Customization

More

MINIMIZING BELT WEAR AND DAMAGE FROM

网页The original chute configuration consisted of a single discharge conveyor, an asymmetrical gate, and two legs, one of which has a rock box at its discharge. The design throughput was 200 tph and the conveyor information used to configure the DEM simulations is shown in Table 1. Table 1.

More

Belt Conveyors: Components, Types, Design, and Applications

网页A belt conveyor is a system designed to transport or move physical items like materials, goods, even people from one point to another. Unlike other conveying means that employ chains, spirals, hydraulics, etc., belt conveyors will move the items using a belt.

More

Belt Conveyor PartsBrief Idea Towards Belt Conveyor Parts

网页Conveyor walkway: Backstop: Take-up: Chutes: Deck plate: Belt sway switch (BSS): Pull cord Switch: Pulleys: The pulleys are mechanical equipment that supports the conveyor belt and also moves the belt, controls its tension, and tracks the conveyor belt. There are different types of pulleys are used in conveyor systems. Head pulley Tail pulley

More

Conveyor Parts and Each of Their Functions - YaleTools

网页Belt is usually made of rubber with a rough surface. 5. Discharge Chute Discharge chute is an outlet for goods that are loaded by the conveyor. 6. Head Pulley The head pulley is a pulley located at the front end of the belt where the material is moved.

More

DETERMINATION OF TRAJECTORY OF MATERIAL LEAVING

网页For design of discharge openings and receiving chutes, it is necessary to know the trajectory of material leaving the head pulley in a conveyor system. Trajectory of material is fixed by the angle of separation of material from the belt and the vertical ordinates from the tangent line drawn at the point of separation on head pulley.

More

Ten Common Mistakes in Conveyor Specification Design

网页When the practices of loading on the transition and half-trough transition are used in combination, the result can be increased belt wear, chute wear, and spillage. Reducing the distance at both the loading and discharge zones by a meter or more of conveyor length can result in a savings of $15,000 to $20,000 per conveyor.

More

Transfer Chutes - West River Conveyors

网页90 Degree Transfer Chute. Transfer Chute with Walkway. West River Conveyors designs underground and overland transfer chutes that improve material flow efficiency and safety when conveying various products. We can also manufacture standalone transfer chutes and ones that are attached to a discharge boom. Our chutes range from simple

More

Primary Dry Sampling Multotec Sampling Equipment Multotec

网页Various custom designs to suit application requirements are undertaken Collect samples from moving conveyors and. Provide sampling solutions from vertical gravity flow streams with vertical chute work between unit processes Minimum disturbance to material streams when sampling Download Brochure Technical Resources View Gallery

More

Components of a Standard Belt Conveyor - Martin Eng

网页A conveyor’s head, or discharge, end will usually consist of the head pulley, a discharge chute along with a belt-cleaning system, a dribble chute, and other equipment to monitor and maintain flow. A transfer point is where the bulk material moves from on piece of equipment to another .

More

Belt Trippers Belt Plows - FEECO International Inc.

网页As the belt passes over the upper pulley, the material is discharged from the belt into a collection chute. The material is then diverted to one side or both sides of the belt for discharge, or back onto the belt if the desired

More

MINIMIZING BELT WEAR AND DAMAGE FROM

网页The original chute configuration consisted of a single discharge conveyor, an asymmetrical gate, and two legs, one of which has a rock box at its discharge. The design throughput was 200 tph and the conveyor information used to configure the DEM simulations is shown in Table 1. Table 1.

More

Chutes - Outotec

网页Chutes are used to transport material from one process step to another. When material is fed into a process or discharged from it, chutes collect, convey and prepare the material flow for the following processing phase. Chutes are used with crushers, feeders, conveyors, stackers, and grinding mills. Contact our sales experts Benefits Customization

More

Conventional transFer Chutes

网页A. Head chute The area surrounding the head pulley of the feeding conveyor B. Drop chute The area where the material is in freefall ... to design a transfer chute between two belt conveyors: A. Rated capacity—tons per hour

More

Transfer Chutes - West River Conveyors

网页A loose liner can damage the conveyor belt or plug a chute, so you need to locate it immediately. SKIRTING The chute skirting is a seal between the chute and the conveyor belt, primarily to prevent material from

More

Top Industrial Belt Conveyor Issues (With Causes

网页Conclusion. Industrial belt conveyors offer reliable handling in nearly any setting, but they can occasionally exhibit issues, particularly if not kept clean and maintained; carryback, mistracking, slippage, and spillage are some

More

40 important question answers on belt conveyor for power

网页2020年6月11日 In this case the scraper is outside the head chute and scrapings must be returned to the head chute by a mechanical chain conveyor or similar. Tertiary scrapers are usually contact scrapers. ... 35-A 1400 mm width inclined belt conveyor has its head pulley at the elevation of 22 meter from ground, is used to convey 45 TPH coal. The

More

DETERMINATION OF TRAJECTORY OF MATERIAL LEAVING

网页For design of discharge openings and receiving chutes, it is necessary to know the trajectory of material leaving the head pulley in a conveyor system. Trajectory of material is fixed by the angle of separation of material from the belt and the vertical ordinates from the tangent line drawn at the point of separation on head pulley.

More

Conveyor Head Pulley - SKE Industries

网页The belt conveyor head pulley is located at the discharge point of conveyor. It drives the conveyor belt. For better traction, the head pulley is usually lagged (with either rubber or ceramic lagging material). Send

More

(PDF) Failure analysis of belt conveyor systems - ResearchGate

网页2009年1月1日 The paper focus on the first step in condition, i.e. estimation of the scale of a problem: the most frequent failures, types and the location of failures and their importance in the context of ...

More

How to design Belt conveyor head funnel - SKE FAQ - SKE

网页2020年8月25日 The head funnel of the belt conveyor is used for guiding materials and controlling the direction of material flow, which avoids the phenomenon of partial load and also plays a role of sealing and dust prevention. If the conveyor’s funnel design is unreasonable, it will lead to the impact of the funnel steel plate and materials, and the

More

Used Head Chutes for sale. Omga equipment more Machinio

网页Manufacturer: Flexicon. ITEM 1810: 3” O. D. X 3 HP FLEXICON DRIVE HEAD WITH DISCHARGE CHUTE. STAINLESS CONSTRUCTION 230/460 VOLTS 9/4.5 AMPS 3 PH 60 HZ FLEX-IN-LINE GEAR DRIVE MODEL # X03-180/180 SERIAL # 7055660900 5:1 RATIO 6” DIAMETE... $2,500 USD.

More

Ten Common Mistakes in Conveyor Specification Design

网页When the practices of loading on the transition and half-trough transition are used in combination, the result can be increased belt wear, chute wear, and spillage. Reducing the distance at both the loading and discharge zones by a meter or more of conveyor length can result in a savings of $15,000 to $20,000 per conveyor.

More