copper ore flotation processing

Estimated Water Requirements for the Conventional

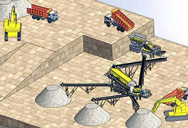

网页Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings. To prepare ore for the flotation process, run-of-mine ore, which may contain from about 2 to 5 percent

More

A Review of the Flotation of Copper Minerals - ResearchGate

网页2017年7月4日 The recovery of these copper minerals by flotation or hydrometallurgy from ores, typically containing 0.5%TCu (open pit mines) and 1-2%TCu (underground mines)

More

Copper extraction - Wikipedia

The average grade of copper ores in the 21st century is below 0.6% copper, with a proportion of economic ore minerals being less than 2% of the total volume of the ore rock. Thus, all mining operations, the ore must usually be beneficiated (concentrated). The concentrate is typically sold to distant smelters, although some large mines have smelters located nearby. Such colocation of

More

Copper processing - Ores Britannica

网页Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores. Native copper is simply the metal found unadulterated in nature. ... In the flotation

More

Copper Ore - an overview ScienceDirect Topics

网页13.5.7.3 Flotation of Copper Ore Copper ore usually contains about 0.5 to 2% copper that occurs in the form of disseminated and stringers. The run of mine ore is reduced from

More

Copper Flotation - Mineral Processing Metallurgy

网页2016年5月16日 A Copper Flotation Flowsheet Because the copper in this type of ore usually assays only plus or minus 1% copper, the porphyry copper operations must be relatively large in order to be commercial.

More

Copper Mining and Processing: Processing Copper Ores

网页A. Processing of Oxide Ore Oxide ores are generally processed using hydrometallurgy. This process uses aqueous (water-based) solutions to extract and purify copper from

More

Flotation of Copper Ores - Mineral Processing

网页2016年2月11日 Flotation of Copper Ores Previous Next Pneumatic flotation is already fully established in a number of places and the results in comparison with the other and older schemes fully justify the opinion of

More

Copper Ore Crushing, Grinding Flotation

网页2017年5月21日 Grinding and Flotation. Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the open-circuit 2600mm x 3960mm (8’-6 x 13’-0) Hardinge rod mill at an average feed rate of 2,106 STPD or

More

Improving the Copper-Molybdenum Ores Flotation

网页The main problems of copper-containing ore processing are: the low copper content ... (Cu–Mo) during the flotation of copper–molybdenum ores is the purpose of this work.

More

Special Issue "Recent Advances in Copper Ore Processing and

网页2022年1月28日 In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, pyrometallurgical, electrometallurgical, and pre-concentration technologies; ... Extensive research has been carried out on the flotation of copper sulphide ore as compared to copper oxide and

More

Estimated Water Requirements for the Conventional

网页Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings. To prepare ore for the flotation process, run-of-mine ore, which may contain from about 2 to 5 percent water, by weight, when mined, is

More

Current Status of Copper-Ore Processing: A Review

网页2021年9月8日 Abstract An analysis of flowsheets for processing sulfide and oxide copper ores, reagent modes, processing equipment, and flotation indicators in some domestic and foreign processing plants and productions is carried out. Autogenous and semiautogenous mills are commonly used in the primary grinding stage in ore

More

Copper extraction - Wikipedia

网页Copper oxide ores are typically treated via chelating-reagent flotation and fatty-acid flotation, which use organic reagents to ensure adsorption onto the mineral surface through the formation of hydrophobic compounds on the mineral surface. [24] [25]

More

Copper processing - Ores Britannica

网页In the flotation process, the finely ground ore, mixed with water and special reagents, is agitated by mechanical and pneumatic devices. These produce air bubbles in the ore-water mixture, or slurry. The reagents

More

Optimizing the Rougher Flotation Process of Copper Ore

网页2019年2月22日 The intercept is zero, because the adjustment led to the regression line passing through the zero value. It must be borne in mind that, although we study a specific flotation process for copper ores, its oxidized degree can vary within a range. Therefore, the range of copper grades in the feed was also chosen as independent variables for its

More

Flotation of Copper Ores - Mineral Processing

网页2016年2月11日 Flotation of Copper Ores Previous Next Pneumatic flotation is already fully established in a number of places and the results in comparison with the other and older schemes fully justify the opinion of

More

Flotation and Tailing Discarding of Copper Cobalt Sulfide Ores

网页The mineral composition of copper–cobalt ores is more complex than that of copper sulfides, and it is also difficult to discard tailing efficiently in primary flotation for the fine-grained disseminated of ore. In this work, a mineral liberation analyzer (MLA) was employed to study the characteristics of minerals. As a significant mineralogical characteristic, the

More

Copper Flotation - Elmhurst College

网页In this manner through a series of steps the copper ore is concentrated to an eventual value of over 28% copper. Waste rock particles do not adhere to the bubbles and drop to the bottom of the tank. The waste material

More

Complete Gold Copper Ore Concentrator Mineral Flotation

网页Complete Gold Copper Ore Concentrator Mineral Flotation Separation Processing Plant Price, Find Details and Price about Gold Mill Gold Ore Processing Plant from Complete Gold Copper Ore Concentrator Mineral Flotation Separation Processing Plant Price - Baichy Heavy Industrial Machinery Co., Ltd.

More

A typical flowsheet used in the flotation process of porphyry copper

网页The copper flotation concentrates produced at the Lubin Concentrator are characterized by polymetallic (Cu-Ag-Pb), polymineral and fine-grained composition, with the lowest content of copper...

More

Copper Ore Processing Methods - Metallurgist Mineral Processing

网页2017年4月11日 Copper Ore Processing Methods The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of concentrating, smelting, and refining.

More

FLOTATION PROCESSING OF COPPER-MOLYBDENUM ORE

网页Keywords: copper-molybdenum ore, flotation, dispergation, concentration, extraction INTRODUCTION As the deposits are depleted and the need arises to involve poor, finely disseminated ores in processing, it becomes necessary to improve the reagent modes of en-richment of copper ores, the use of additives and rea-

More

Flotation ore dressing Britannica

网页The flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to waste in gravity concentration plants. Flotation has now become the

More

Special Issue "Recent Advances in Copper Ore Processing and

网页2022年1月28日 In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, pyrometallurgical, electrometallurgical, and pre-concentration technologies; improving copper ore resource efficiency through application of integrated approaches.

More

Copper-processing technologies: Growing global copper supply

网页2023年2月17日 Primary sulfides are typically processed at plants using flotation-based systems. Flotation is generally economical for ores with levels of copper that are greater than 0.25 percent, 5 from which flotation can recover 85 to 90 percent. Ores lower than this grade are normally discarded as waste.

More

Current Status of Copper-Ore Processing: A Review

网页2021年9月8日 For oxide copper ore and some sulfide ores, a combined flotation–hydrometallurgy technology is applied to produce copper concentrate and copper cathodes. The processing of this ore includes ore preparation, flotation, concentrate leaching, and solvent extraction and electrowinning (SXEW).

More

Optimizing the Rougher Flotation Process of Copper Ore

网页2019年2月22日 To model the copper ore flotation process, an analysis was made on the factors that affect the results of the process. We choose the following seven factors as independent variables. Table 1 shows the values of the case of a condition. Table 1 Predictive variables of the tons of fine copper in percentage evaluated at the point of the

More

Flotation and Tailing Discarding of Copper Cobalt Sulfide Ores

网页The mineral composition of copper–cobalt ores is more complex than that of copper sulfides, and it is also difficult to discard tailing efficiently in primary flotation for the fine-grained disseminated of ore. In this work, a mineral liberation analyzer (MLA) was employed to study the characteristics of minerals. As a significant mineralogical characteristic, the

More

Copper Processing Multotec

网页Copper processing uses physical, mechanical and / or chemical methods to convert run-of-mine (ROM) copper ore to high-quality, pure copper. A wide range of mineral processing equipment is used in converting the

More

Copper Ore Processing Methods - Metallurgist

网页2017年4月11日 Copper Ore Processing Methods The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of

More

Flotation of an Oxidized Copper Sulfide Ore - ResearchGate

网页2017年1月1日 Copper sulfide minerals are mined at copper mines and concentrated by flotation process. In recent years, the mining of refractory copper ores, which is difficult to concentrate by...

More

FLOTATION PROCESSING OF COPPER-MOLYBDENUM ORE

网页Keywords: copper-molybdenum ore, flotation, dispergation, concentration, extraction INTRODUCTION As the deposits are depleted and the need arises to involve poor, finely disseminated ores in processing, it becomes necessary to improve the reagent modes of en-richment of copper ores, the use of additives and rea-

More

Complete Gold Copper Ore Concentrator Mineral Flotation

网页Complete Gold Copper Ore Concentrator Mineral Flotation Separation Processing Plant Price, Find Details and Price about Gold Mill Gold Ore Processing Plant from Complete Gold Copper Ore Concentrator Mineral Flotation Separation Processing Plant Price - Baichy Heavy Industrial Machinery Co., Ltd.

More

Flotation ore dressing Britannica

网页The flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to waste in gravity concentration plants. Flotation has now become the

More

Copper ore flotation process - YouTube

网页The flotation machine is used for the separation of the nonferrous black metal as well as the separation of the non-metallic materials such as the coal fluor...

More

(PDF) Effect of wet ball milling on copper ore flotation by fractal ...

网页2023年3月15日 Particles morphology has considerable impacts in flotation process. Variations in particles morphology have been studied by different methods, including fractal geometry. ... on copper ore ...

More

Froth flotation - Wikipedia

网页The flotation process is used for the separation of a large range of sulfides, carbonates and oxides prior to further refinement. Phosphates and coal are also upgraded (purified) by flotation technology. "Grade-recovery

More