grinding copper change

Copper Flotation: Effects of Particle Size, Grinding and

网页2010年10月6日 In the current research work, influences of particle size, grinding time, and agitation rate on the flotation of a copper sample from Sungun copper mine (E.

More

Precision grinding and facing of copper-beryllium alloys

网页1999年10月1日 When experimenting with polycrystalline aluminum, which has a similar FCC lattice as copper, these authors found a “drastic change” of cutting force when

More

Physical and Chemical Changes - Chemistry Socratic

网页Acting upon matter can cause it to change, but it is useful to separate these changes into two different categories: physical and chemical. A chemical change describes a process

More

How to grind copper? - Information - More SuperHard

网页2021年2月2日 The grinding copper material is easy to stick to the surface of the grinding wheel and cause scratches as the grinding wheel rotates. It is not easy to improve the gloss. We can improve the pore of its

More

Grinding Wheels for Copper McMaster-Carr

网页for Aluminum, Brass, and Copper Also known as Type 27, raised- hub, and depressed-center cutoff wheels, these wheels outperform Type 1 wheels when making flush cuts.

More

Is grinding CuSO4 5 H2O physical or chemical change? - Answers

网页2009年10月5日 Best Answer. Copy. CuSO4 (copper sulphate) 5 H2O is hydrated, containing water. The crystals (blue-coloured) are still present i believe, and so if you

More

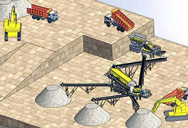

extraction crushing and grinding process of copper Ore

网页2013年5月22日 The copper extraction process takes place through open-pit mining using large-scale is suitable for grinding copper ore. global copper mill – extraction Global

More

Health issues with grinding bras, copper, aluminum

网页2008年3月16日 Brass contains copper, which is evidently a strong lung irritant. Aluminum can also be a lung irritant, but not as severe as copper. So those of you using a dremel,

More

Metallography of copper and copper alloys insight Struers

网页Consequently, grinding can cause deep deformation in high purity copper, while grinding and polishing abrasives can be pressed into the surface. Copper alloys are harder, but still have a tendency to form scratches. In some bronzes, these scratches may occur in some individual grains only.

More

Copper Precision Grinding Services GlobalSpec

网页from Products Finishing, Inc. The following details our grinding capabilities and equipment. We can provide cylindrical grinding and centerless grinding services. If you have any questions or would like to receive a Free Quote, please fill out our online form or give us a call anytime at 814-452-4887.

More

(PDF) SIZE REDUCTION BY GRINDING METHODS - ResearchGate

网页2017年3月4日 The electric power consumption by this process run on ore mining and processing enterprises is variously estimated as a value from 5 to 20% of overall world electric power. The objective of this ...

More

Grinding Wheels for Copper McMaster-Carr

网页for Aluminum, Brass, and Copper Also known as Type 27, raised- hub, and depressed-center cutoff wheels, these wheels outperform Type 1 wheels when making flush cuts. Angle Grinder Cutoff Wheels for Aluminum, Brass, and Copper Straight Grinder Cutoff Wheels for Aluminum, Brass, and Copper

More

Physical and Chemical Changes - Chemistry Socratic

网页Physical changes change the shape, size or phase of a substance. Crumpling paper, getting a haircut, dissolving salt in water, melting wax, making ice cubes, chopping veggies for tossed salad, growing crystals from a supersaturated solution, grinding metal and slicing bread are all physical changes.

More

Eight tips for effective grinding - The Fabricator

网页2013年6月3日 In an ideal world, every shop would have an ammeter handy. Hooked to the tool, an ammeter reveals whether the operator is pushing too hard or not hard enough. The pressure can change depending on what the tool and grinding wheel are rated for, but optimal pressure in a general industrial grinding application usually draws between 8

More

Quick Change Discs Norton Abrasives

网页Quick Change Discs Quick Change Discs Quick-change discs provide exceptional grinding, deburring and blending flexibility in smaller areas with a twist-on and -off fastening system. This tool-free attachment design makes fast work of disc changes to maximize productivity and minimize downtime.

More

New Applications for Electrochemical Grinding

网页2019年12月25日 The grinding wheels Tridex uses range in size from 0.004 to 4.0 inches wide. These standard wheels will work for most applications, although workpiece materials such as copper or titanium

More

Robotic Grinding Automated Material Removal

网页Automated Robotic grinding is an application where PushCorp's equipment excels. Our precise force and constant speed end effectors account for part variability and abrasive wear. Therefore, manual

More

Is grinding CuSO4 5 H2O physical or chemical change? - Answers

网页2009年10月5日 See answer (1) Best Answer Copy CuSO4 (copper sulphate) 5 H2O is hydrated, containing water. The crystals (blue-coloured) are still present i believe, and so if you grind the crystals down, you...

More

Is heating CuSO4 5H20 a chemical change or a physical change

网页In our lab, we heated copper sulfate pentahydrate (Cuso4 H20) after grinding it. Our observations included a color change from blue to white, which led us to believe it was a chemical...

More

Metallographic grinding and polishing insight

网页Fine grinding produces a surface with little deformation that can easily be removed during polishing. Because of the drawbacks with grinding papers, alternative fine grinding composite surfaces are available, in order to

More

Dimensional Changes After Heat Treatment - Vacaero

网页2013年5月7日 The dimensional changes on hardening and tempering should be added together. The minimum recommended machining allowance is 0.15% per side, assuming that stress relief is performed

More

Type 27 Grinding Wheels McMaster-Carr

网页Long-Life Grinding Wheels forAngle Grinders— Use on Metals. Wheels are a blend of aluminum oxide and zirconia alumina, which removes more material and lasts three times as long as our General Purpose Grinding Wheels. They are also known as Type 27 wheels, raised-hub wheels, and grinding discs.

More

Metallographic grinding and polishing insight

网页Grinding removes material using fixed abrasive particles that produce chips of the specimen material (see below). The process of making chips with a sharp abrasive grain produces the lowest amount of deformation in the

More

Copper Precision Grinding Services GlobalSpec

网页from Products Finishing, Inc. The following details our grinding capabilities and equipment. We can provide cylindrical grinding and centerless grinding services. If you have any questions or would like to receive a Free Quote, please fill out our online form or give us a call anytime at 814-452-4887.

More

(PDF) Increasing the grind size for effective liberation and flotation ...

网页2016年5月26日 The crushing, grinding, combined native copper sulphide and good microwave-heating phase gra in size distributions are presented in Figure 5. It is c learly se en that under the sam e crushing ...

More

(PDF) SIZE REDUCTION BY GRINDING METHODS - ResearchGate

网页2017年3月4日 The electric power consumption by this process run on ore mining and processing enterprises is variously estimated as a value from 5 to 20% of overall world electric power. The objective of this...

More

How to Process Copper Ore: Beneficiation Methods

网页2023年3月13日 Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the

More

Eight tips for effective grinding - The Fabricator

网页2013年6月3日 In an ideal world, every shop would have an ammeter handy. Hooked to the tool, an ammeter reveals whether the operator is pushing too hard or not hard enough. The pressure can change depending on what the tool and grinding wheel are rated for, but optimal pressure in a general industrial grinding application usually draws between 8

More

12.3 Primary Copper Smelting - US EPA

网页12.3 Primary Copper Smelting 12.3.1 General1 Copper ore is produced in 13 states. In 1989, Arizona produced 60 percent of the total ... Crushing and grinding systems used in ore, flux, and slag processing also contribute to fugitive dust problems. Control of SO2 from smelters is commonly performed in a sulfuric acid plant. Use of a

More

Robotic Grinding Automated Material Removal

网页Automated Robotic grinding is an application where PushCorp's equipment excels. Our precise force and constant speed end effectors account for part variability and abrasive wear. Therefore, manual

More

Dimensional Changes After Heat Treatment - Vacaero

网页2013年5月7日 The dimensional changes on hardening and tempering should be added together. The minimum recommended machining allowance is 0.15% per side, assuming that stress relief is performed

More

Is heating CuSO4 5H20 a chemical change or a physical change

网页In our lab, we heated copper sulfate pentahydrate (Cuso4 H20) after grinding it. Our observations included a color change from blue to white, which led us to believe it was a chemical...

More

8 Principles of Centerless Grinding - Metal Cutting Corporation

网页With the in-feed method, the regulating wheel spins the part at one speed while pushing it towards the grinding wheel, which is spinning at a faster speed. The greater the difference in speeds, the faster the removal rate. 4. The choice of grinding wheel is critical. Another key factor in centerless grinding is the choice of grinding wheel.

More

5 Grinding Considerations for Improving Surface Finish

网页2021年1月26日 1) Grinding Operational Parameters Adjusting the grinding parameters can be the easiest and fastest solution to improve a part’s surface finish. Here are key parameters and recommended actions to do it successfully. This component is ground to a surface finish of 3.0 microinch Ra.

More

Type 27 Grinding Wheels McMaster-Carr

网页Long-Life Grinding Wheels forAngle Grinders— Use on Metals. Wheels are a blend of aluminum oxide and zirconia alumina, which removes more material and lasts three times as long as our General Purpose Grinding Wheels. They are also known as Type 27 wheels, raised-hub wheels, and grinding discs.

More

Transparency on greenhouse gas emissions from mining to enable ... - Nature

网页2020年2月3日 The climate change impacts of mining are often not fully accounted for, although the environmental impact of mineral extraction more generally is widely studied. Copper mining can serve as a case ...

More- << Previous:Sale Of Grinding Machines In Bolivia

- >> Next:Spesifikasi Vertical Mill