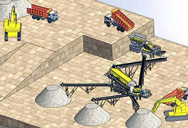

meganite iron ore crushing circuit

Eco-efficient and cost-effective process design for magnetite iron

网页2015年2月24日 Option 1. PC/AGC/RMS/PM/CMS. Primary crushing – AG milling in closed circuit with hydrocyclones and pebble crushing – rougher magnetic separation –

More

Processing of Magnetite Iron Ores - Comparing Grinding Options

网页The results of a theoretical option study for high capacity processing of a hard, fine-grained silica-rich magnetite ore is presented in this paper, with the emphasis on comminution

More

Processing of Magnetite Iron Ores–Comparing Grinding

网页2009年1月1日 Kiruna iron ore deposit (Kiirunavaara) operated by LKAB is the world's largest and most modern underground iron mine (McNab et

More

A review of modeling and control strategies for cone crushers

网页Cone crusher Modeling Control Optimization Crushing circuit Comminution circuit ABSTRACT Run-of-mine ore is usually too large to be useful for construction or

More

Energy and Environmental Profile of the U.S. Mining

网页The crushing stages will reduce the iron ore from several feet in diameter at the primary stage to six inches down to one-half or three- ... 4.1.2.2 Grinding In the grinding circuit,

More

Processing of Magnetite Iron Ores - Comparing Grinding Options

网页Although the majority of current steel production is supported by iron ore sourced from high-grade haematite deposits, the long-term growing demand for steel has led to higher raw

More

Crushing Energy Efficiency - North American Mining Magazine

网页2021年6月10日 Another option to help improve comminution efficiency is in-pit crushing and conveying. The advantage here is found in the transportation of ore between mine

More

Secondary Tertiary Crushing Circuits - Mineral

网页2015年7月24日 This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing be done in

More

Magnetite Ore Crushing Plant,Magnetite Ore Crushing

网页Magnetite ore is a significant ore of iron, it is black or brownish-black with a metallic luster, has a Mohs hardness of 5–6 and a black streak. Magnetite ore beneficiation process is divided into crushing, grinding,

More

Meganite Iron Ore Crushing Circuitfrom Sudan - HN droled mine

网页Meganite iron ore crushing circuit - gold ore crusher.Iron beneficiation plant, crusher machine.Developing new type of iron ore for cone crusher. Our leading products have

More

Eco-efficient and cost-effective process design for magnetite iron ore ...

网页2015年2月24日 Option 1. PC/AGC/RMS/PM/CMS. Primary crushing – AG milling in closed circuit with hydrocyclones and pebble crushing – rougher magnetic separation – pebble milling – cleaner magnetic separation. Option 1 resembles the well-known fully autogenous LKAB and Cleveland Cliffs style, low operating cost operations.

More

Simheuristic-based decision support system for ... - ScienceDirect

网页2020年9月1日 Each stage is composed of dozens of pieces of equipment, such as crushers, screens, and feeders. The processed ore size defines the type and position of each stage. For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m.

More

Processing of Magnetite Iron Ores–Comparing

网页2009年1月1日 Kiruna iron ore deposit (Kiirunavaara) operated by LKAB is the world's largest and most modern underground iron mine (McNab et al., 2009; Poveromo, 2000). Mining in Kiruna started in 1902 shortly ...

More

thyssenkrupp to deliver next gen gyratory crushers to

网页2020年4月21日 These high capacity crushers are considered to be the largest and most powerful in the world and are unrivalled when it comes to crushing blasted hard rock and ore.” The KB 63-130 type gyratory

More

Energy and Environmental Profile of the U.S. Mining

网页The crushing stages will reduce the iron ore from several feet in diameter at the primary stage to six inches down to one-half or three- ... 4.1.2.2 Grinding In the grinding circuit, rod, ball, or autogenous mills grind the taconite down into even smaller uniformed-sized particles. The ore is ground less than 325 mesh, and in some cases less ...

More

A review of modeling and control strategies for cone crushers

网页Cone crusher Modeling Control Optimization Crushing circuit Comminution circuit ABSTRACT Run-of-mine ore is usually too large to be useful for construction or metallurgy. Large particles must be reduced to specific sizes to either comply with aggregate sizing regulations, or facilitate mineral liberation; therefore, in

More

METHODS FOR CRUSHING OPERATIONAL CONTROL

网页Figure 1 illustrates the plant design that processes up to 6,000t/h of iron ore (itabirites) came from Conceição and Dois Córregos Mines (MG, Brazil). The primary crushing stage consists of one gyratory crusher with 2 meters of gape in Conceição I. The product of the primary crusher is classified by double deck screens (64 and

More

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

网页2015年4月3日 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore. Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 8.5 % in

More

Design of Comminution Circuit for Optimum Performance of

网页characteristics of the ore on impact and thus helps in selecting the crusher types that will be most efficient, the number of crushing stages and the overall crushing circuits. 2. Materials and Methods 2.1 Materials The materials used in the course of this project included the flowsheet of the existing iron ore processing plant,

More

Mining and Ore Handling Mining, Minerals Metals

网页2022年7月5日 Mining Ore Handling. Advanced automation and condition monitoring solutions to optimize mining mobile assets. Edge control and analytics to improve machine performance of stacker reclaimers,

More

11.24 Metallic Minerals Processing - US EPA

网页A single crushing operation likely includes a hopper or ore dump, screen(s), crusher, surge bin, apron feeder, and conveyor belt transfer points. Emissions from these various pieces of equipment are often ducted to a single control device. The emission factors provided in Tables 11.24-1 and 11.24-2 for

More

Simheuristic-based decision support system for ... - ScienceDirect

网页2020年9月1日 The processed ore size defines the type and position of each stage. For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m. In the quaternary crushing stage, the size of the ore that feeds the crushers is less than 20 mm. Screens classify the ore by size and ...

More

11.23 Taconite Ore Processing - US EPA

网页of the processed ore shipped to the iron and steel industry is in the form of pellets. Other forms of processed ore include sinter and briquettes. The average iron content of pellets is 63 percent. 11.23.2 Process Description2-5,41 Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles,

More

Iron Mining Process - Minnesota Iron

网页Crushing At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is separated from the taconite using magnetism.

More

Simheuristic-based decision support system for ... - ScienceDirect

网页2020年9月1日 The processed ore size defines the type and position of each stage. For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m. In the quaternary crushing stage, the size of the ore that feeds the crushers is less than 20 mm. Screens classify the ore by size and ...

More

Simheuristic-based decision support system for ... - ScienceDirect

网页2020年9月1日 Each stage is composed of dozens of pieces of equipment, such as crushers, screens, and feeders. The processed ore size defines the type and position of each stage. For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m.

More

thyssenkrupp to deliver next gen gyratory crushers to

网页2020年4月21日 These high capacity crushers are considered to be the largest and most powerful in the world and are unrivalled when it comes to crushing blasted hard rock and ore.” The KB 63-130 type gyratory

More

Processing of Magnetite Iron Ores–Comparing

网页2009年1月1日 Kiruna iron ore deposit (Kiirunavaara) operated by LKAB is the world's largest and most modern underground iron mine (McNab et al., 2009; Poveromo, 2000). Mining in Kiruna started in 1902 shortly ...

More

11.24 Metallic Minerals Processing - US EPA

网页A single crushing operation likely includes a hopper or ore dump, screen(s), crusher, surge bin, apron feeder, and conveyor belt transfer points. Emissions from these various pieces of equipment are often ducted to a single control device. The emission factors provided in Tables 11.24-1 and 11.24-2 for

More

METHODS FOR CRUSHING OPERATIONAL CONTROL

网页Figure 1 illustrates the plant design that processes up to 6,000t/h of iron ore (itabirites) came from Conceição and Dois Córregos Mines (MG, Brazil). The primary crushing stage consists of one gyratory crusher with 2 meters of gape in Conceição I. The product of the primary crusher is classified by double deck screens (64 and

More

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

网页2015年4月3日 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore. Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 8.5 % in

More

11.23 Taconite Ore Processing - US EPA

网页of the processed ore shipped to the iron and steel industry is in the form of pellets. Other forms of processed ore include sinter and briquettes. The average iron content of pellets is 63 percent. 11.23.2 Process Description2-5,41 Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles,

More

Mining and Ore Handling Mining, Minerals Metals - Emerson

网页2022年7月5日 Mining Ore Handling. Advanced automation and condition monitoring solutions to optimize mining mobile assets. Edge control and analytics to improve machine performance of stacker reclaimers, conveyors, crushers, optimize crushing circuit performance and track energy consumption.

More

Design of Comminution Circuit for Optimum Performance of

网页characteristics of the ore on impact and thus helps in selecting the crusher types that will be most efficient, the number of crushing stages and the overall crushing circuits. 2. Materials and Methods 2.1 Materials The materials used in the course of this project included the flowsheet of the existing iron ore processing plant,

More

Iron Mining Process - Minnesota Iron

网页Crushing At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is separated from the taconite using magnetism.

More

Mineral Processing - Crushing - Plant design, construction,

网页Bench scale and pilot scale design for comminution circuits Factors influencing the selection of comminution circuits Types and characterisation of crusher equipment and circuit flowsheet Selection and sizing of primary crusher Computer aided design of Jaw Crusher Selection and sizing of secondary and tertiary crushers Optimising the Eccentric speed of

More

Perfecting the Performance of Secondary Crushers E MJ

网页The role of the secondary crushing circuit, like every other stage in mineral processing flowsheets, is to prepare the feed material for the next stage of the process. The equipment selected depends on the characteristics of the ore and the desired end-product. ... In 2020, Weir Minerals replaced a competitor cone crusher within an iron-ore ...

More

Calculating the value of iron ores in ironmaking and steelmaking

网页2011年1月1日 This paper describes the use of the Marx value in use (VIU) model to quantify the downstream value of iron ores. The Marx model consists of heat and mass balance modules for sintering, pelletising ...

More